Back around late 2004, I had successfully completed a Heads-Up Display (HUD) project on my ’94 Altima SE which other members of this forum had already proven was very feasible. That project was very rewarding to me and it left a nice imprint in my psyche. Back then, I also envisioned that someday another project of that scale – an Automatic Digital Climate Control system – might also be within my capabilities and someday a reality. (http://www.nissanclub.com/forums/showpost.php?p=2270842&postcount=14)

I’ve made numerous remarks hinting and doing absolutely nothing in regards about it.

(http://www.nissanclub.com/forums/showpost.php?p=2295873&postcount=4)

(http://www.nissanclub.com/forums/showpost.php?p=2330557&postcount=11)

Well the time has come where I will either eat my words or otherwise prove that with determination and commitment many things are possible, however remote they may seem.

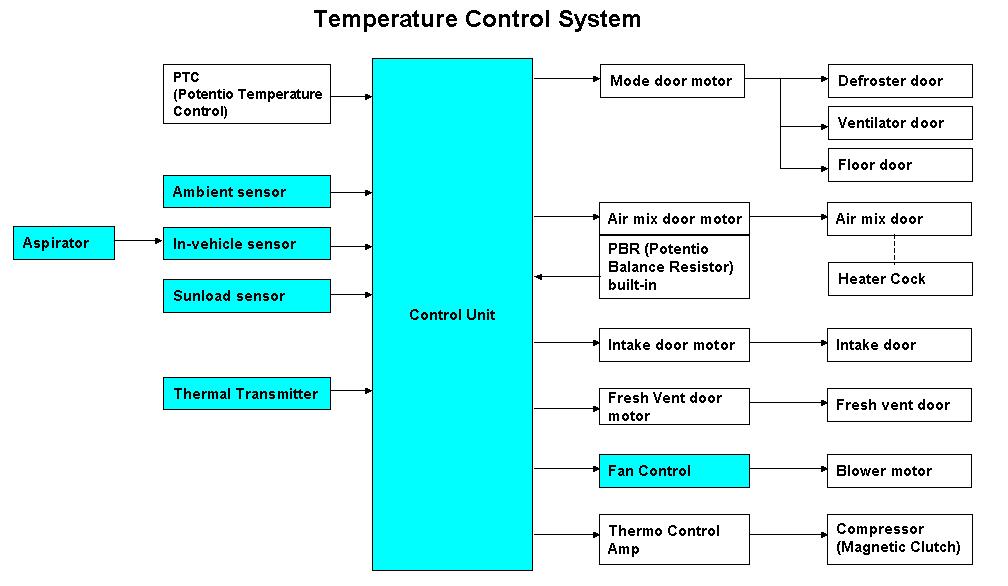

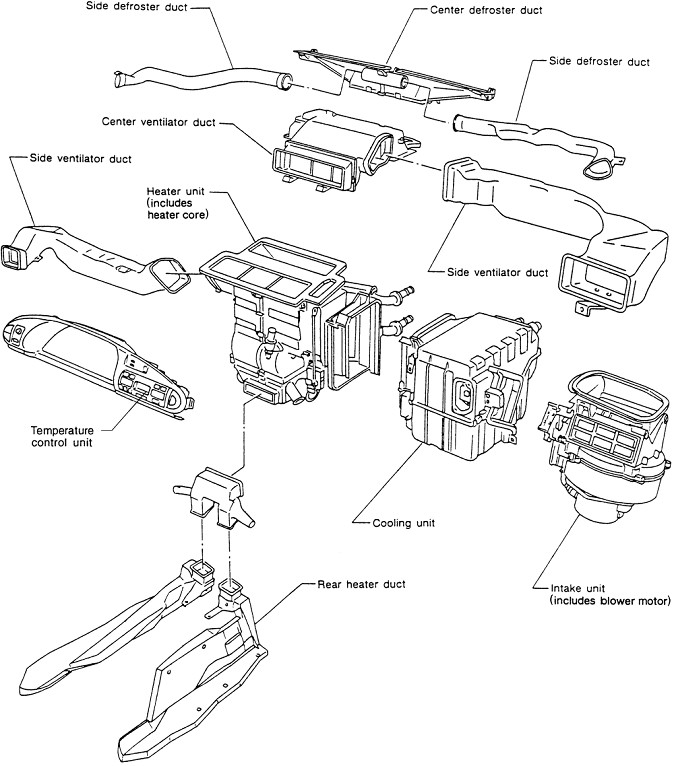

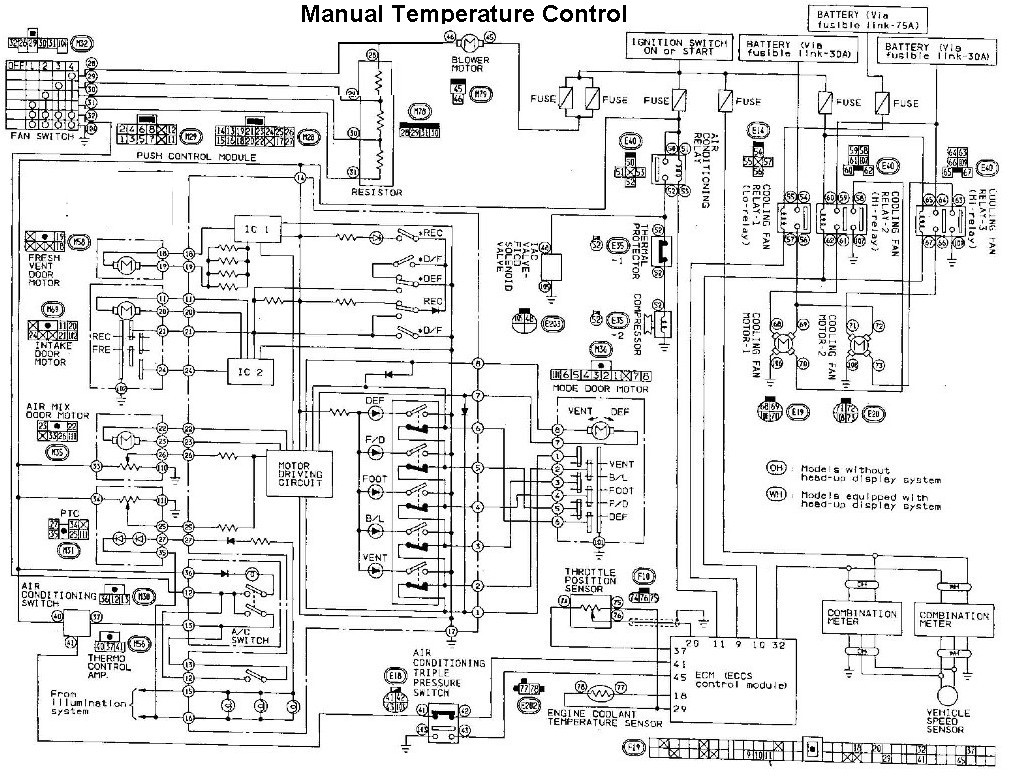

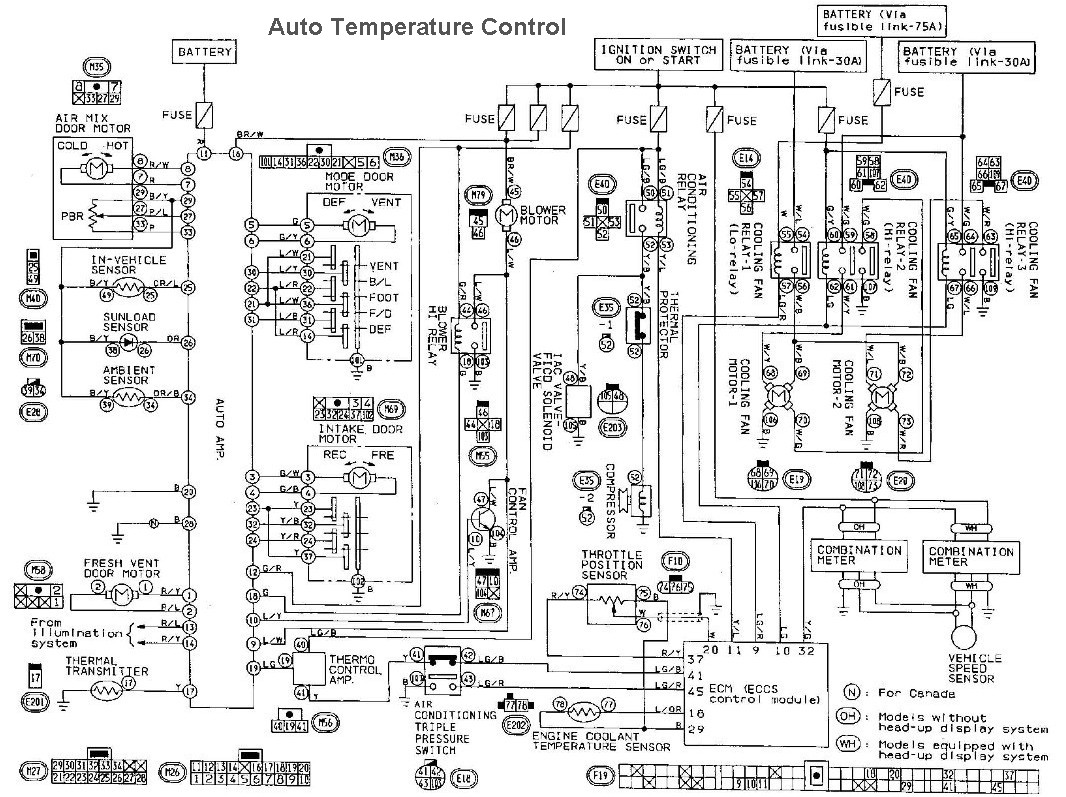

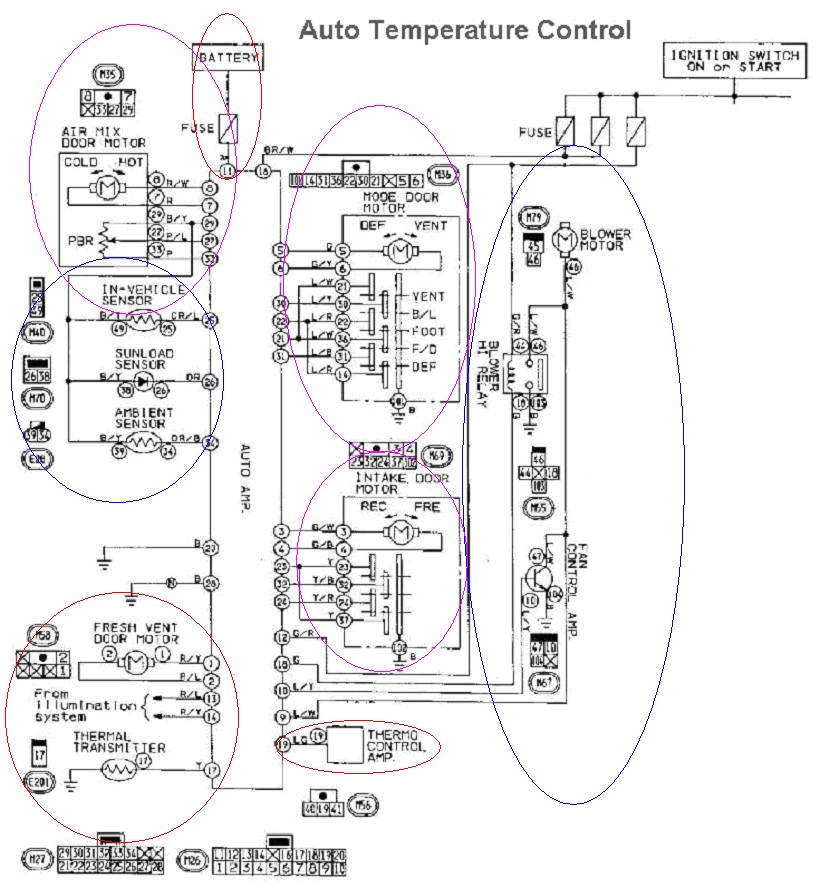

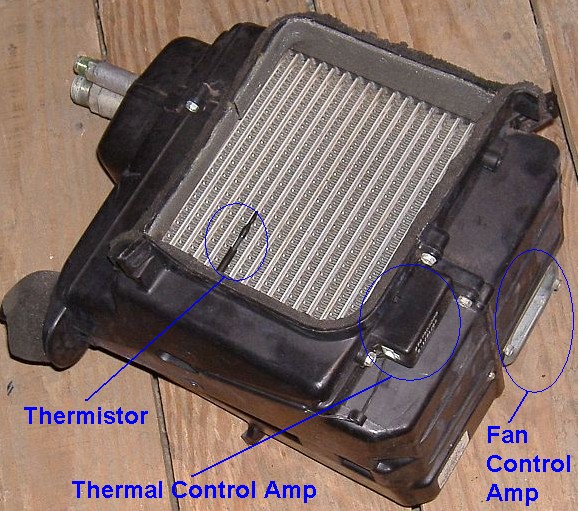

With this post I hope to begin a process that will build over time and show some of the steps taken to produce a fully functional manual temperature control to automatic digital climate control conversion. Anyone that will like to follow along or participate in other ways are fully welcome.

This project is dedicated to all those members that take pride in keeping alive the Altima and sharing their knowledge.

Enjoy,

jserrano

I’ve made numerous remarks hinting and doing absolutely nothing in regards about it.

(http://www.nissanclub.com/forums/showpost.php?p=2295873&postcount=4)

(http://www.nissanclub.com/forums/showpost.php?p=2330557&postcount=11)

Well the time has come where I will either eat my words or otherwise prove that with determination and commitment many things are possible, however remote they may seem.

With this post I hope to begin a process that will build over time and show some of the steps taken to produce a fully functional manual temperature control to automatic digital climate control conversion. Anyone that will like to follow along or participate in other ways are fully welcome.

This project is dedicated to all those members that take pride in keeping alive the Altima and sharing their knowledge.

Enjoy,

jserrano